5R3VX1800

BELTWORTH

4010390000

| Availability: | |

|---|---|

| Quantity: | |

The BELTWORTH V-banded belts and cogged V-banded belts are an excellent choice for virtually any application where increased horsepower capacity or output is needed. Or where conventional, single or multiple belt drives are impractical because of space or weight limitations.

BELTWORTH 's banding process assures smoother, more quiet operation. the specially compounded wrap construction is ideal for clutching operations. And it won't turn over or jump off the drive. It's oil and heat resistant and antistatic, too. Typical applications for banded V-Belts include vertical shaft drives, V-Flat drives and clutching drives. Banded V-Belts are recommended for use where belts vibrations or blet whip causes unsatisfactory results when conventional multiple V-belts are used. They are available in Classical cross sections as (A, B, C, & D), narrow cross sections as, (3V, SV, & 8V). And Metric cross sections as (SPA, SPB, SPC), The Raw edge cogged banded cross sections are: (RAX, RBX, RCX, R3VX, R5VX, R8VX)

| 1. Tope Surface 2. Chloroprene compound with transverse oriented fiber 3. Polyester tension cord. maintenance-free 4. Chloroprene compound with transverse oriented fiber 5. Abrasion-resistant cover fabric | ||||

| 1. Tope Surface 2. Upper belt structure 3. Polyester tension cord. low maintenance 4. Embedding compound 5. Chloroprene compound with transverse oriented fiber 6. Moulded cogs | ||||

Characteristics: 1. Maintenance-free 4. High power transmission capability 5. Frame material: polyester string, cord |

| ||||

Profiles | |||||

Section | Top width(mm) | Height(mm) | Pitch Distance(mm) | Length Range (inch) | |

RA(AJ) | 13 | 10 | 15.9 | 47"-197" | |

RB(BJ) | 17 | 13 | 19 | 47"-394" | |

RC(CJ) | 22 | 16 | 25.5 | 79"-590" | |

RD(DJ) | 32 | 21.5 | 37 | 157"-590" | |

RE(EJ) | 38 | 27 | 44.5 | 196"-708" | |

R3V(9NJ) | 9.7 | 9.7 | 10.3 | 47"-197" | |

R5V(15NJ) | 15.7 | 16 | 17.5 | 59"-394" | |

R8V(25NJ) | 25.4 | 25 | 28.6 | 79"-394" | |

RSPA | 13.6 | 12 | / | 47"-197" | |

RSPB | 17 | 16.5 | / | 59"-394" | |

RSPC | 22 | 21 | / | 118"-492" | |

RAX | 13 | 10 | 15.9 | 24"-150" | |

RBX | 17 | 13 | 19 | 50"-195" | |

RCX | 22 | 16 | 25.5 | 100"-195" | |

R3VX | 9.7 | 10 | 10.3 | 24"-150" | |

R5VX | 15.8 | 16 | 17.5 | 50"-200" | |

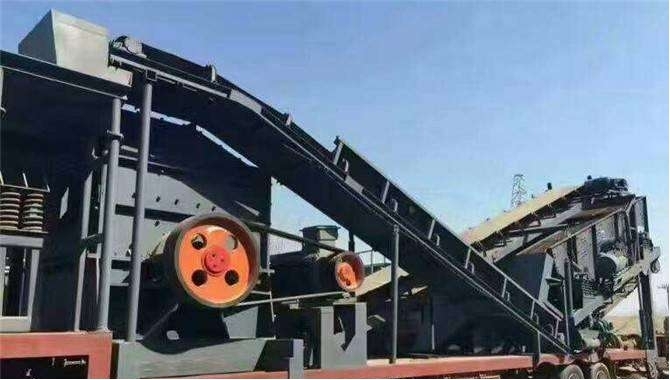

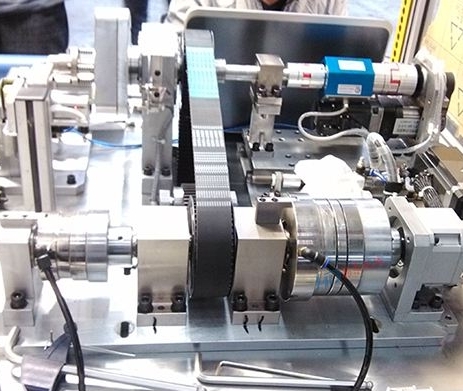

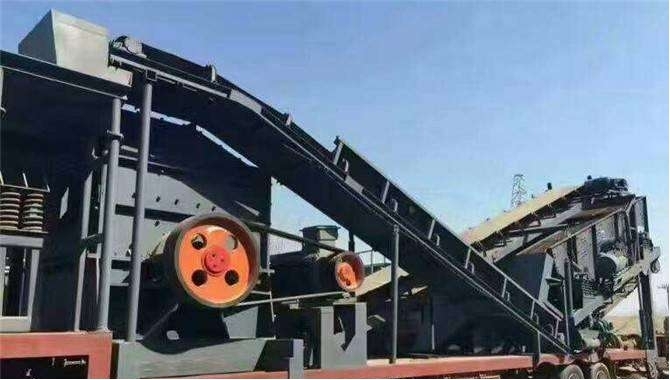

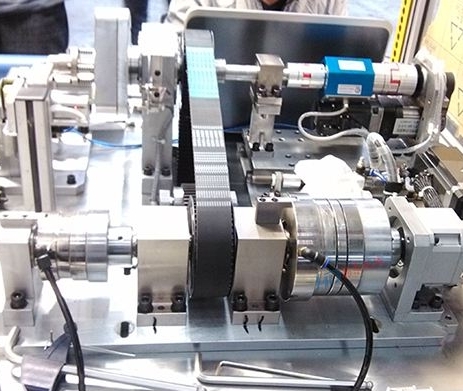

Application: Most of banded V belts are primarily used for special problem solutions in mechanical engineering and commercial vehicle construction.

|  |

|  |

Banded V belts offer a number of advantages over other types of belts. They are more durable and have a higher resistance to heat, making them ideal for use in high-temperature applications. Banded V belts also provide greater power transmission efficiency and can handle higher loads than other types of belts.

Banded V belts are most commonly used in office machines, consumer durables, cars, and light trucks. They are also used in agricultural equipment, lawn and garden equipment, and a variety of industrial machinery. Banded V belts provide good resistance to heat, oil, abrasion, and weather.

In order to keep your banded v belt in good condition and operating properly, it is important to follow a few simple steps. First, always make sure that the belt is properly tensioned. If the belt is too loose, it can slip and cause damage to the pulleys. Second, keep the belt clean and free of debris. A build-up of dirt and grime can cause the belt to wear down prematurely. Finally, inspect the belt regularly for signs of wear or damage. If you notice any issues, replace the belt as soon as possible to avoid further damage.

Banded v belts are a type of power transmission belt that is commonly used in industrial and automotive applications. They are made up of two or more layers of reinforce material, with each layer typically being a different width. The banded construction helps to distribute the load evenly and prevent the belt from slipping.

The BELTWORTH V-banded belts and cogged V-banded belts are an excellent choice for virtually any application where increased horsepower capacity or output is needed. Or where conventional, single or multiple belt drives are impractical because of space or weight limitations.

BELTWORTH 's banding process assures smoother, more quiet operation. the specially compounded wrap construction is ideal for clutching operations. And it won't turn over or jump off the drive. It's oil and heat resistant and antistatic, too. Typical applications for banded V-Belts include vertical shaft drives, V-Flat drives and clutching drives. Banded V-Belts are recommended for use where belts vibrations or blet whip causes unsatisfactory results when conventional multiple V-belts are used. They are available in Classical cross sections as (A, B, C, & D), narrow cross sections as, (3V, SV, & 8V). And Metric cross sections as (SPA, SPB, SPC), The Raw edge cogged banded cross sections are: (RAX, RBX, RCX, R3VX, R5VX, R8VX)

| 1. Tope Surface 2. Chloroprene compound with transverse oriented fiber 3. Polyester tension cord. maintenance-free 4. Chloroprene compound with transverse oriented fiber 5. Abrasion-resistant cover fabric | ||||

| 1. Tope Surface 2. Upper belt structure 3. Polyester tension cord. low maintenance 4. Embedding compound 5. Chloroprene compound with transverse oriented fiber 6. Moulded cogs | ||||

Characteristics: 1. Maintenance-free 4. High power transmission capability 5. Frame material: polyester string, cord |

| ||||

Profiles | |||||

Section | Top width(mm) | Height(mm) | Pitch Distance(mm) | Length Range (inch) | |

RA(AJ) | 13 | 10 | 15.9 | 47"-197" | |

RB(BJ) | 17 | 13 | 19 | 47"-394" | |

RC(CJ) | 22 | 16 | 25.5 | 79"-590" | |

RD(DJ) | 32 | 21.5 | 37 | 157"-590" | |

RE(EJ) | 38 | 27 | 44.5 | 196"-708" | |

R3V(9NJ) | 9.7 | 9.7 | 10.3 | 47"-197" | |

R5V(15NJ) | 15.7 | 16 | 17.5 | 59"-394" | |

R8V(25NJ) | 25.4 | 25 | 28.6 | 79"-394" | |

RSPA | 13.6 | 12 | / | 47"-197" | |

RSPB | 17 | 16.5 | / | 59"-394" | |

RSPC | 22 | 21 | / | 118"-492" | |

RAX | 13 | 10 | 15.9 | 24"-150" | |

RBX | 17 | 13 | 19 | 50"-195" | |

RCX | 22 | 16 | 25.5 | 100"-195" | |

R3VX | 9.7 | 10 | 10.3 | 24"-150" | |

R5VX | 15.8 | 16 | 17.5 | 50"-200" | |

Application: Most of banded V belts are primarily used for special problem solutions in mechanical engineering and commercial vehicle construction.

|  |

|  |

Banded V belts offer a number of advantages over other types of belts. They are more durable and have a higher resistance to heat, making them ideal for use in high-temperature applications. Banded V belts also provide greater power transmission efficiency and can handle higher loads than other types of belts.

Banded V belts are most commonly used in office machines, consumer durables, cars, and light trucks. They are also used in agricultural equipment, lawn and garden equipment, and a variety of industrial machinery. Banded V belts provide good resistance to heat, oil, abrasion, and weather.

In order to keep your banded v belt in good condition and operating properly, it is important to follow a few simple steps. First, always make sure that the belt is properly tensioned. If the belt is too loose, it can slip and cause damage to the pulleys. Second, keep the belt clean and free of debris. A build-up of dirt and grime can cause the belt to wear down prematurely. Finally, inspect the belt regularly for signs of wear or damage. If you notice any issues, replace the belt as soon as possible to avoid further damage.

Banded v belts are a type of power transmission belt that is commonly used in industrial and automotive applications. They are made up of two or more layers of reinforce material, with each layer typically being a different width. The banded construction helps to distribute the load evenly and prevent the belt from slipping.