980XH

BELTWORTH

4010350000

| Color: | |

|---|---|

| Size: | |

| Material: | |

| Cord: | |

| Fabric: | |

| Availability: | |

| Quantity: | |

The BELTWORTH synchronous belt(Timing belt) drive is composed of a closed annular tape with equidistant teeth on the inner surface (the material of timing belt: rubber and PU/polyurethane) and corresponding pulleys. When the transmission is working, the teeth of the synchronous belt mesh with the tooth slots of the pulley to transmit motion and power, so it has various advantages of gear transmission, chain transmission and belt transmission. The synchronous belt drive has an accurate transmission ratio, no slip, can obtain a constant speed ratio, stable transmission, shock absorption, low noise, and a large transmission ratio range, generally up to 1:10, and the allowable linear speed can reach 40m/s. The transmission efficiency is high, generally reaching 98%-99%. Delivering power from a few watts to hundreds of kilowatts. The compact structure is also suitable for multi-axis transmission, with low tension force, no lubrication, and no pollution, so it can work normally in situations where pollution is not allowed and the working environment is relatively harsh.

Products Description:

Structure:

Belt body: The imported CR rubber or HNBR rubber with high quality from Japanese company

Reinforcement: The imported fiberglass cord with excellent quality from Japanese company or German company.

Belt tooth: Nylon 66 fabric with high spandex as the tooth protection materials.

Characteristic:

1. Excellent dynamic curve performance

2. Crack resistant

3. Ozone resistant

4. Anti-aging

5. Heat Resistant

6. Wear resistant

Double Tooth Synchronous Belt (Timing Belt):

There are two types tooth for the Double Tooth Synchronous Belt (Timing Belt

DA type is Symmetrical Tooth.

DB type is staggered Tooth.

The width of the Synchronous Belt (Timing Belt)

The width is 450mm to 480mm

MOQ is 1 sleeve (we have existing molds) to 5 sleeves (we have no existing mold)

The customers can cut the available width with sleeve cutting machine according to their requirement

Open End Rubber Synchronous Belt (Timing Belt)

We can deliver open endless Synchronous Belt (Timing Belt) as produced one time, there is black fabric on the surface and the tooth. The max width of belt is 10mm to 120mm for all types. Profiles are 3M,5M,8M,14M, S3M, S5M, S8M, MXL, XL, L, H etc. The length is cut to order, or can be purchased as a full roll. Specialized for applications such as conveying, linear motion, metering, positioning, etc. Normally, our clients need the rubber open endless Synchronous Belt (Timing Belt) as the widths are 10mm, 12mm, 15mm and 25mm, the length is 100 meters per roll.

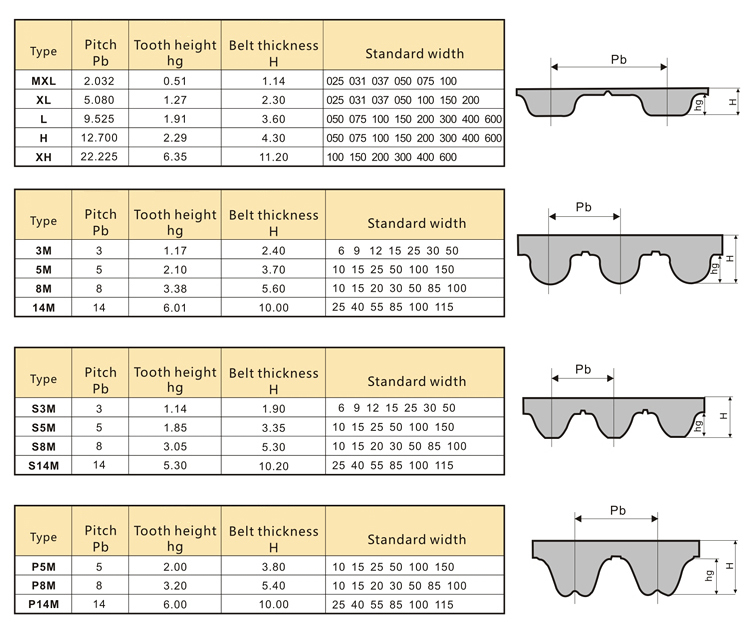

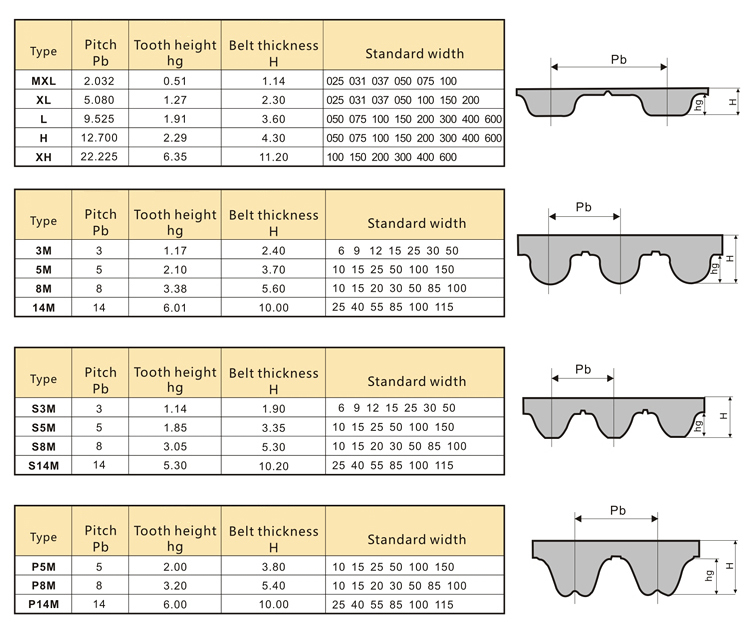

Belt Profile:

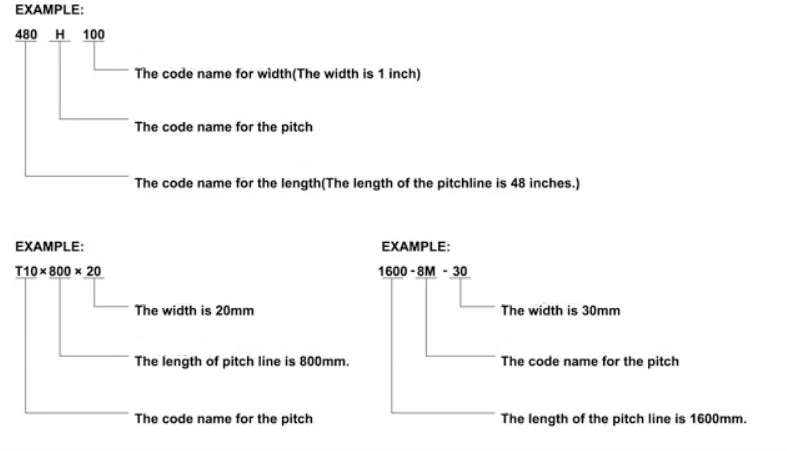

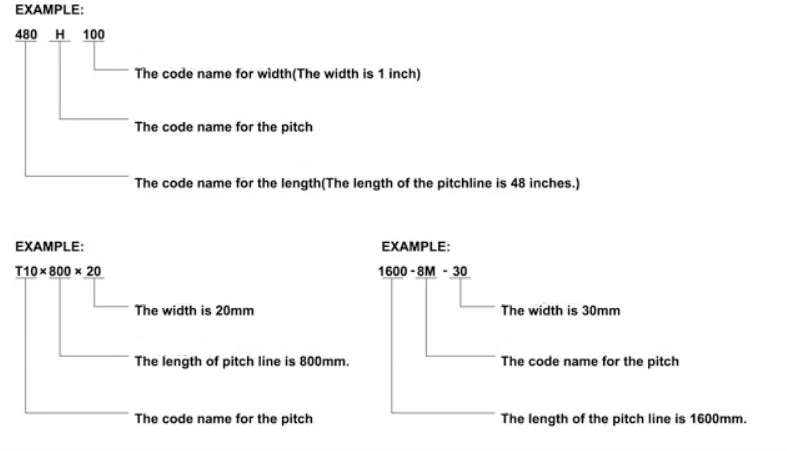

Example of Marking:

Application:

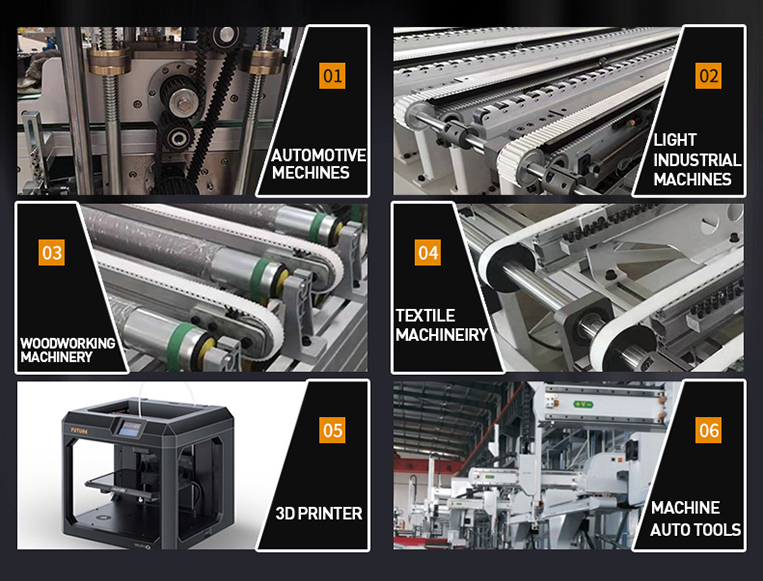

Widely used in automobile, tobacco, textile, printing, glass, chemical industry, light industry, metallurgy, instrumentation, mining, petroleum, machine tools, SMT, computer printing, food packaging and other mechanical equipment transmission.

XH type industrial timing belts offer a variety of advantages over other types of belts, making them ideal for a wide range of applications. Here are some of the key benefits:

Higher Power Capacity: XH type belts can handle higher loads and speeds than other types of belts, making them ideal for high-power applications.

Improved Efficiency: XH type belts run more smoothly and with less vibration than other types of belts, resulting in improved efficiency and longer belt life.

Reduced Maintenance Costs: The superior design of XH type belts results in reduced maintenance costs and downtime.

XH type industrial timing belts are used in a variety of industries and applications. Common uses for XXH type timing belts include: automotive, manufacturing, robotics, and aerospace.

XH type timing belts are known for their strength and durability. They are often used in high-stress applications where other types of belts would fail. XXH type timing belts can handle high loads and speeds, making them ideal for use in automotive and manufacturing applications.

Robotics is another common application for XH type timing belts. These belts can handle the high speeds and frequent starts and stops associated with robotic systems. XH type timing belts are also used in some aerospace applications because of their ability to handle extreme temperatures.

XH Type Industrial Timing Belt is a high quality product that has been designed for use in a variety of industries. The belt is made of a durable material that can withstand the rigors of industrial use. The belt has been designed to operate in a variety of environments and can be used in a wide range of applications.

1. What is a timing belt?

A timing belt is a type of belt that helps to keep the engine in synchronization. It ensures that the crankshaft and camshaft rotate at the correct speed, which allows for proper engine operation.

2. Why is it important to have a properly functioning timing belt?

A properly functioning timing belt is essential for keeping the engine running smoothly. If the timing belt breaks or slips, it can cause serious engine damage. In some cases, it can even cause the engine to seized up completely.

3. How often should I replace my timing belt?

It is typically recommended that you replace your timing belt every 40,000 miles or so. However, this may vary depending on the make and model of your vehicle. Consult your owner’s manual or a qualified mechanic for more specific information.

The BELTWORTH synchronous belt(Timing belt) drive is composed of a closed annular tape with equidistant teeth on the inner surface (the material of timing belt: rubber and PU/polyurethane) and corresponding pulleys. When the transmission is working, the teeth of the synchronous belt mesh with the tooth slots of the pulley to transmit motion and power, so it has various advantages of gear transmission, chain transmission and belt transmission. The synchronous belt drive has an accurate transmission ratio, no slip, can obtain a constant speed ratio, stable transmission, shock absorption, low noise, and a large transmission ratio range, generally up to 1:10, and the allowable linear speed can reach 40m/s. The transmission efficiency is high, generally reaching 98%-99%. Delivering power from a few watts to hundreds of kilowatts. The compact structure is also suitable for multi-axis transmission, with low tension force, no lubrication, and no pollution, so it can work normally in situations where pollution is not allowed and the working environment is relatively harsh.

Products Description:

Structure:

Belt body: The imported CR rubber or HNBR rubber with high quality from Japanese company

Reinforcement: The imported fiberglass cord with excellent quality from Japanese company or German company.

Belt tooth: Nylon 66 fabric with high spandex as the tooth protection materials.

Characteristic:

1. Excellent dynamic curve performance

2. Crack resistant

3. Ozone resistant

4. Anti-aging

5. Heat Resistant

6. Wear resistant

Double Tooth Synchronous Belt (Timing Belt):

There are two types tooth for the Double Tooth Synchronous Belt (Timing Belt

DA type is Symmetrical Tooth.

DB type is staggered Tooth.

The width of the Synchronous Belt (Timing Belt)

The width is 450mm to 480mm

MOQ is 1 sleeve (we have existing molds) to 5 sleeves (we have no existing mold)

The customers can cut the available width with sleeve cutting machine according to their requirement

Open End Rubber Synchronous Belt (Timing Belt)

We can deliver open endless Synchronous Belt (Timing Belt) as produced one time, there is black fabric on the surface and the tooth. The max width of belt is 10mm to 120mm for all types. Profiles are 3M,5M,8M,14M, S3M, S5M, S8M, MXL, XL, L, H etc. The length is cut to order, or can be purchased as a full roll. Specialized for applications such as conveying, linear motion, metering, positioning, etc. Normally, our clients need the rubber open endless Synchronous Belt (Timing Belt) as the widths are 10mm, 12mm, 15mm and 25mm, the length is 100 meters per roll.

Belt Profile:

Example of Marking:

Application:

Widely used in automobile, tobacco, textile, printing, glass, chemical industry, light industry, metallurgy, instrumentation, mining, petroleum, machine tools, SMT, computer printing, food packaging and other mechanical equipment transmission.

XH type industrial timing belts offer a variety of advantages over other types of belts, making them ideal for a wide range of applications. Here are some of the key benefits:

Higher Power Capacity: XH type belts can handle higher loads and speeds than other types of belts, making them ideal for high-power applications.

Improved Efficiency: XH type belts run more smoothly and with less vibration than other types of belts, resulting in improved efficiency and longer belt life.

Reduced Maintenance Costs: The superior design of XH type belts results in reduced maintenance costs and downtime.

XH type industrial timing belts are used in a variety of industries and applications. Common uses for XXH type timing belts include: automotive, manufacturing, robotics, and aerospace.

XH type timing belts are known for their strength and durability. They are often used in high-stress applications where other types of belts would fail. XXH type timing belts can handle high loads and speeds, making them ideal for use in automotive and manufacturing applications.

Robotics is another common application for XH type timing belts. These belts can handle the high speeds and frequent starts and stops associated with robotic systems. XH type timing belts are also used in some aerospace applications because of their ability to handle extreme temperatures.

XH Type Industrial Timing Belt is a high quality product that has been designed for use in a variety of industries. The belt is made of a durable material that can withstand the rigors of industrial use. The belt has been designed to operate in a variety of environments and can be used in a wide range of applications.

1. What is a timing belt?

A timing belt is a type of belt that helps to keep the engine in synchronization. It ensures that the crankshaft and camshaft rotate at the correct speed, which allows for proper engine operation.

2. Why is it important to have a properly functioning timing belt?

A properly functioning timing belt is essential for keeping the engine running smoothly. If the timing belt breaks or slips, it can cause serious engine damage. In some cases, it can even cause the engine to seized up completely.

3. How often should I replace my timing belt?

It is typically recommended that you replace your timing belt every 40,000 miles or so. However, this may vary depending on the make and model of your vehicle. Consult your owner’s manual or a qualified mechanic for more specific information.